Dec. 19, 2024

Silicone Optics for High-Lumen LED LightingSilicone optics are advanced optical components that offer numerous benefits for high-performance applications, particularly in LED lighting systems. These LED lenses are made from a specialized optical clear liquid silicone material that imparts several advantageous characteristics, making them ideal for use in high-power and high-lumen LED lighting solutions. Let's dive into some of their key features:

1. High and Low-Temperature Resistance

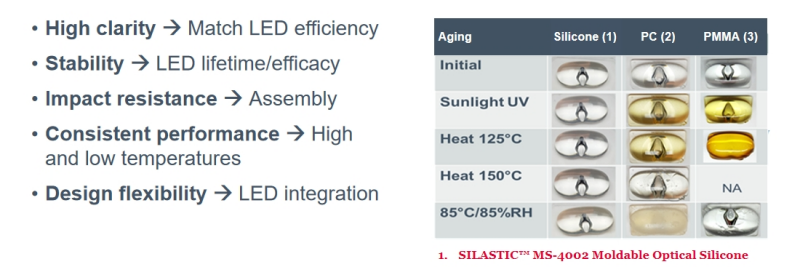

· Temperature Extremes: Silicone optics are known for their exceptional thermal stability. They can endure both high and low-temperature environments, typically ranging from -40°C to +150°C, making them suitable for outdoor and industrial applications.

· Thermal Durability: This high temperature resistance helps maintain optical clarity and structural integrity over time, even in the most demanding conditions, such as those experienced in automotive, outdoor lighting, and industrial settings.

| Moldable Silicone | PC | PMMA | Glass |

|---|

| Light Transmission (%) | 94 | 88-90 | 93 | 95 |

| Refractive Index | 1.42 | 1.58 | 1.49 | 1.52 |

| UV Resistance | High | Low | Medium | High |

| Chemical Resistance | Medium | Medium | Low | High |

| Service Temperature Max. (℃) | > 150 | 120 | 90 | > 200 |

| Yellowing | Low | High | High | Low |

| Micro Detail Replication | High | Low | Medium | Low |

| Ability to Mold Large/Thick Parts | High | Low | Low | Medium |

| Minimum Thickness | < 0.5mm | 2mm | 2mm | - |

| Draft Angle° (Manufacturing) | < 0 | 1 to 2 | 1 to 2 | - |

| Weight | Low | Medium | Medium | High |

| Flexible Material- Integration | High | Low | Low | Low |

2. Anti-Yellowing

· UV and Aging Resistance: Silicone materials have a natural resistance to UV degradation and yellowing, unlike traditional plastic lenses. This property is particularly important for applications exposed to sunlight or other harsh environmental factors, ensuring the lens maintains its transparency and light transmission over the years.

· Long-Term Aesthetics: The anti-yellowing feature ensures that the silicone optics retain their optical performance and aesthetic appeal, contributing to the longevity of the product and reducing the need for frequent replacements.

3. Flexibility

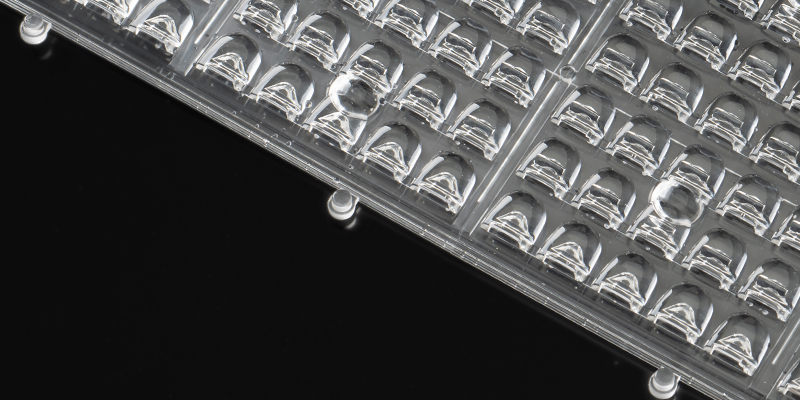

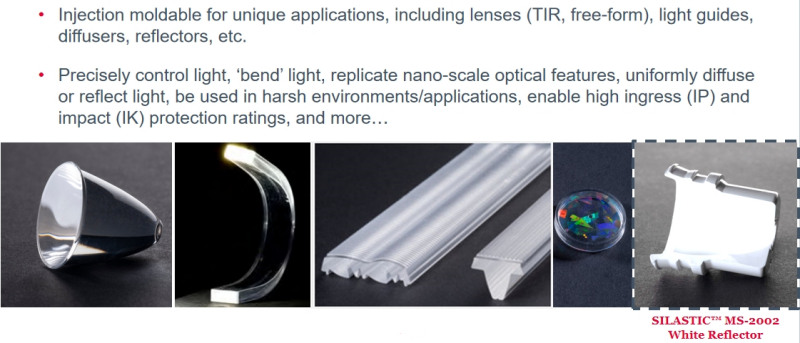

· Design Versatility: Silicone optics are highly flexible, which allows for more intricate and customized designs. The flexibility of optical silicone makes it easier to mold into complex shapes, ideal for creating optical lenses with specific focal lengths, beam patterns, and other optical characteristics tailored to the needs of the lighting system.

· Shock Absorption: The flexibility also contributes to the optics' ability to absorb shocks and vibrations, which is beneficial for applications in environments where impacts or movements are common.

4. Waterproof Sealing and Durability

· Integrated Waterproofing: Silicone optics can be designed with a built-in waterproof sealing ring, eliminating the need for an external shell or housing. This feature enhances the overall durability of the lighting system and prevents water or moisture ingress, which can damage the LED components.

· No Need for Additional Housing: By eliminating the need for an external protective shell, the design becomes simpler, lighter, and more cost-effective. This feature reduces manufacturing complexity and improves the long-term reliability of the lighting system.

5. Long Lifetime and Cost Savings

· Extended Service Life: Due to their high durability, resistance to environmental factors, and stable performance over time, silicone optics have a much longer lifespan compared to traditional plastic lenses. This longevity significantly reduces the need for replacements and maintenance, leading to lower overall operational costs.

· Cost Efficiency: While the initial investment in silicone optics may be higher than conventional materials, the long-term savings from reduced replacements, less maintenance, and improved energy efficiency make silicone lenses a more economical choice over time.

Applications

· High-Power LED Lighting: Silicone optics are ideal for high-power and high-lumen LED lighting systems, helping efficiently direct and focus light output while maintaining optical clarity over extended periods.

· Energy-Efficient Lighting Solutions: These optical lenses are widely used in energy-efficient, high-brightness applications, such as street lighting, automotive headlights, architectural lighting, and spotlights.

· Automotive Lighting: Silicone optics can be used in automotive headlamps, tail lights, and indicator lights, where both light efficiency and durability are important.

· Street Lighting: LED street lights benefit from silicone optics to direct light precisely where it is needed, improving road safety while reducing light pollution.

· Architectural and Decorative Lighting: The ability to mold silicone into intricate shapes makes it ideal for decorative lighting applications in both commercial and residential spaces.

· Industrial and Commercial Spotlights: Silicone optics are used in high-performance LED fixtures that need to manage large amounts of heat and light, such as those found in shopping malls, factories, or warehouses.

Silicone optics offer a combination of high temperature resistance, anti-yellowing properties, flexibility, and long-term durability. These features make them particularly advantageous for high-power LED lighting systems, offering enhanced performance, longevity, and cost-effectiveness. YEJIA Optical specializes in manufacturing high-quality and precision silicone optics. If you're looking for a trusted manufacturer of optical silicone lenses, contact us today.