Jul. 25, 2024

When do your LED lighting fixtures need to use silicone lenses?

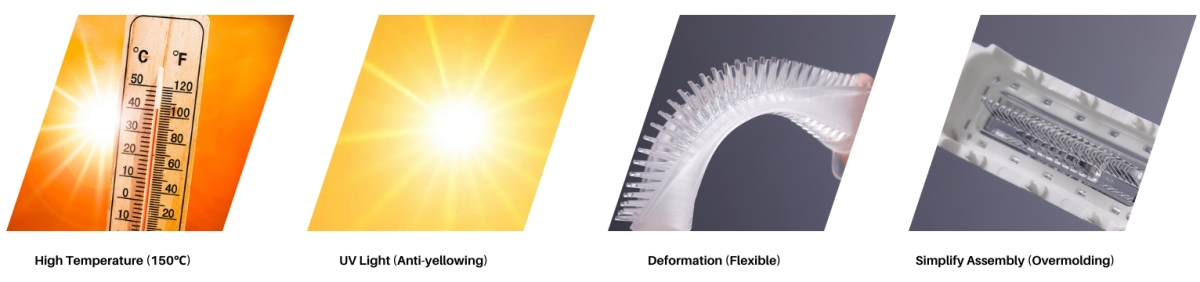

Silicone lenses are increasingly favored in the market due to their excellent high-temperature resistance, yellowing resistance, UV resistance, and good flexibility. However, does your LED lighting design really require silicone lenses? Before making a decision, be sure to consider the following points:

If the LED lighting needs to be used for an extended period in high temperatures (e.g., 150 degrees Celsius) or under UV exposure, or if you notice burning or yellowing when using plastic lenses, then silicone lenses would be a better choice.

In certain applications, the LED lens may need to deform under stress. Silicone lenses, with their superior elastic properties, can easily meet this requirement.

For specific situations like industrial lights or explosive environments, if the LED lighting lens needs to have explosion-proof and flame-resistant characteristics, then flexible silicone lenses will be the ideal choice.

If the LED lens has a complex shape, including micro-structure, sharp angles or undercut structures, or if you need to simplify the assembly process by overmolding with materials like plastic or tempered glass, then silicone lenses will be your best choice.

If you are seeking high light transmittance and lightweight design, silicone lenses will be your preferred option. Compared to glass or optical plastic materials, silicone lenses have a lower density and lighter weight, helping to effectively reduce the product weight.

Liquid injection molding optical silicon lens is essentially an upgrade over optical PC lens and PMMA lens, showing superior performance in light transmittance, high-temperature resistance, UV resistance, and yellowing resistance compared to plastic lenses. However, silicone lenses also have some disadvantages, such as higher mold precision requirements leading to increased mold costs, and higher raw material costs compared to optical plastic materials, which can raise the overall product cost. When choosing whether to use silicone lenses, it is essential to comprehensively evaluate the product's performance or structural requirements and consider the costs of molds and products to provide customers with a high cost-effective product.

Yejia Optical is a leading manufacturer specializing in producing high-quality silicone lenses with precision and expertise in LSR molding and overmolding. Our lenses have been supplied to numerous well-known LED light manufacturers. If you require LED lighting fixtures for high-temperature and UV environments with strict anti-yellowing requirements, then silicone lenses are the perfect choice for you. Looking for a reliable silicone lens manufacturer, please feel free to get in touch with us today.